1-Panel Primed MDF

1-3/4″ Thick – Interior Door

LEARN ABOUT THIS DOOR

1-PANEL PRIMED MDF INTERIOR DOOR,

1-3/4″ Thick

This 1-panel contemporary door is 100% made in the USA at our northern Colorado factory (near Fort Collins). Our MDF doors are manufactured for interior applications (inside the home), and should not be used in (and are not warrantied for) exterior door (entry door) applications. Key elements of this door include:

Warranty

An industry-leading Warranty is provided for this door, including a five-year limited warranty. The five-year warranty applies only to the construction of the door, and not the factory-applied Prime finish.

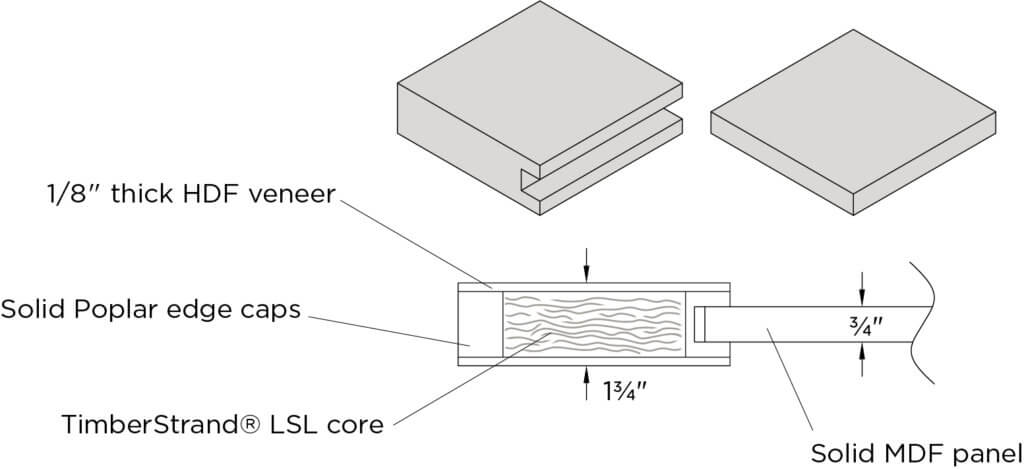

Engineered Stiles and Rails

Stiles and rails are the vertical and horizontal “frame” components, respectively, of the door. Our stiles and rails are engineered to resist bowing and warping. We use industry-leading 1/8″ thick MDF veneers, with superior quality TimberStrand® Laminated Strand Lumber (LSL) core material, and solid Poplar edge caps (for mounting hinges).

Solid MDF Panels

Panels are the large, wider boards that fill the space between the stiles and rails. Our panels are solid 3/4″ thick MDF—much higher quality than thinner (1/2″) composite or hollow core panels.

Cope and Stick Construction

Our doors are assembled with “cope and stick” (i.e., tongue and groove-type) construction. Stiles and rails are glued together for optimum strength and stability. Panels fit into grooves in the stile and rail components.

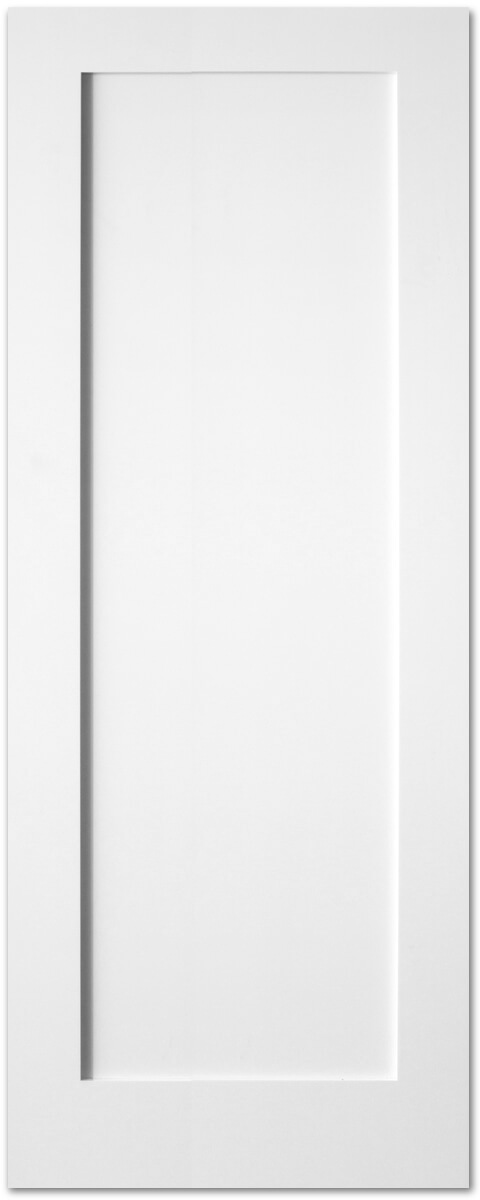

Panel and Sticking Profile

This door features a contemporary flat panel and a square sticking profile as shown below. “Sticking” is the profile of wood on the stiles and rails, creating a “picture frame” around the panels of the door.